Grinding and polishing stones require precision and high-performance tools to achieve the desired finish. One crucial tool in this process is the grinding disc abrasive. Our company have made significant advancements in this field to provide users with more efficient and effective polishing solutions over the years. A full set of polishing disc consist of metal disc, resin disc and buff disc.

Metal bond diamond grinding disc is mainly used for rough and medium grinding processes on granite, marble, concrete and other stones. It is designed with fast aggressive diamond segment and strong round steel base, which can be strongly installed on polishing head for grinding purpose. The distance between diamond segments and uniformity distribution prevent dust and avoid scratching.

Resin bond diamond grinding disc is used for fine polishing granite, marble and other stone slabs on automatic polishing lines or manual polishing machines. Resin bond diamond grinding discs are usually used after metal bond diamond grinding disc.

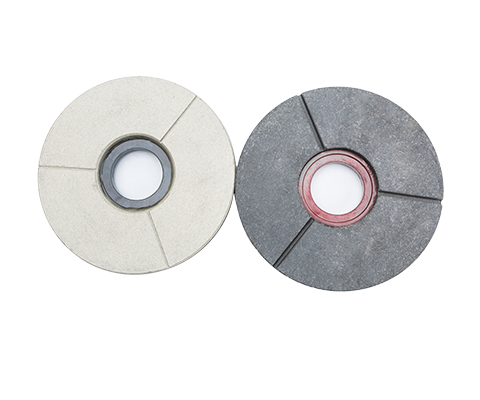

Resin bond buff diamond polishing disc is a wool made pressed polishing disc for final process of stone polishing. Black, white and red three buff polishing discs are available for different needs of stone colors. Black and white buff discs are widely used for dark and light color stones respectively, while red buff disc is sometimes required for polishing red and brown stones. Other colors are available upon requirement. It’s applicable for automatic, semi-automatic and manual polishing machines. Different colors, sizes and grits for different demands.

Post time: Aug-28-2023